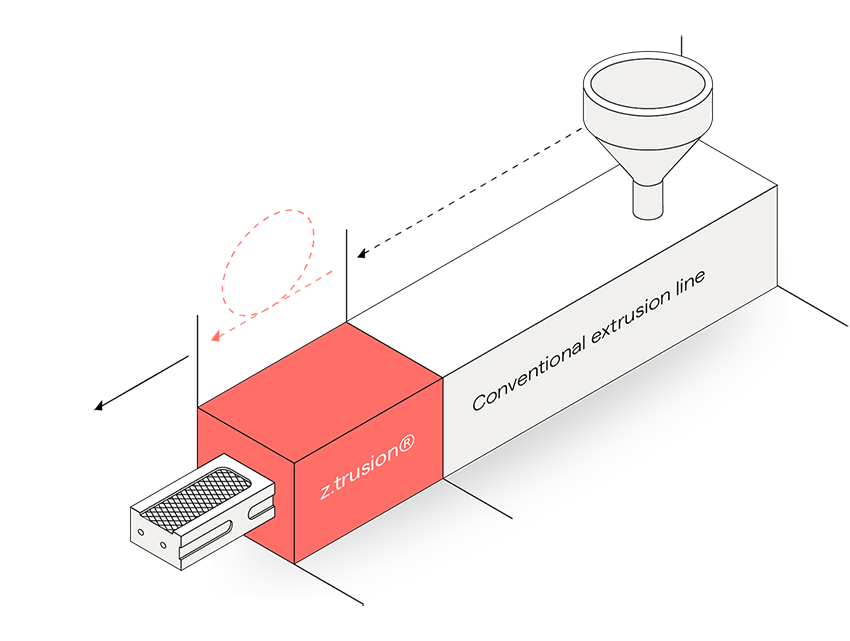

Introducing z.trusion®

A small change with a big impact

The z.trusion® technology enables you to produce complex 3D structured components in polymers, rubber, aluminium, ceramics, composites and bio-composites. By simply replacing your existing extrusion setup with z.trusion®, you can open up to big improvements, such as:

- Reducing carbon footprint

- Reducing production costs

- Differentiating your product

- Unlocking endless design possibilities

Cut costs and realise product ideas

Observing great product ideas never reaching the mass market due to production costs inspired our technology. z.trusion® helps you to realise your creative product ideas whilst freeing up valuable resources.

Energy reduction

Material reduction

Time reduction

Production cost reduction