The world needs z.truded® fuel cell plates

The fuel cell technology, with its ability to produce electricity with little to no emissions, is widely considered the key technology to speed up the energy transition.

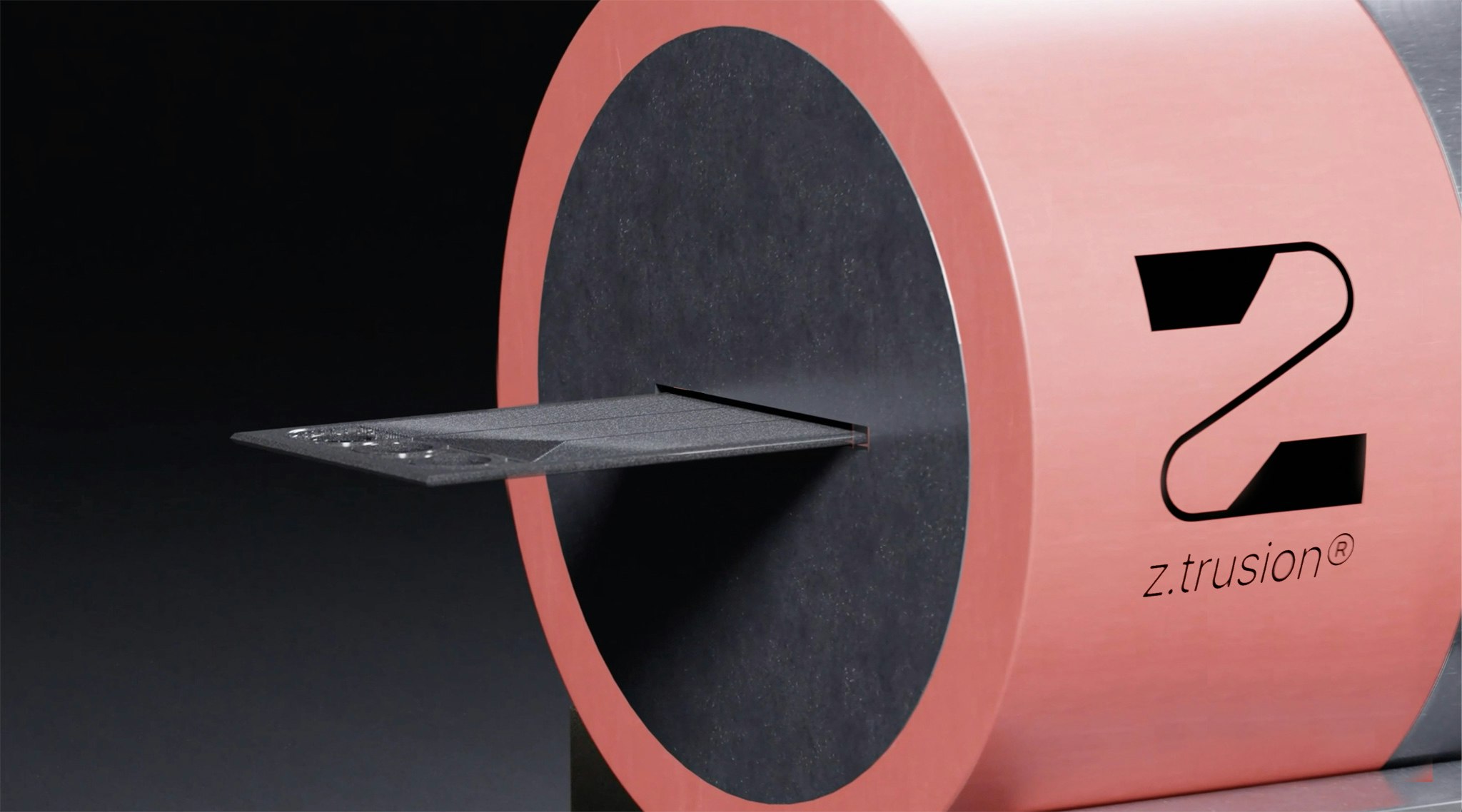

By building a pilot plant in Sweden for mass production of bipolar fuel cell plates with the z.trusion® technology, we are now rapidly scaling up. Thereby, addressing the world’s urgent need for more effective energy systems.

"With z.trusion®, we see the potential to cut production time of fuel cell plates from minutes to seconds."

Marcus Berggren, CTO at Reliefed, home of z.trusion®

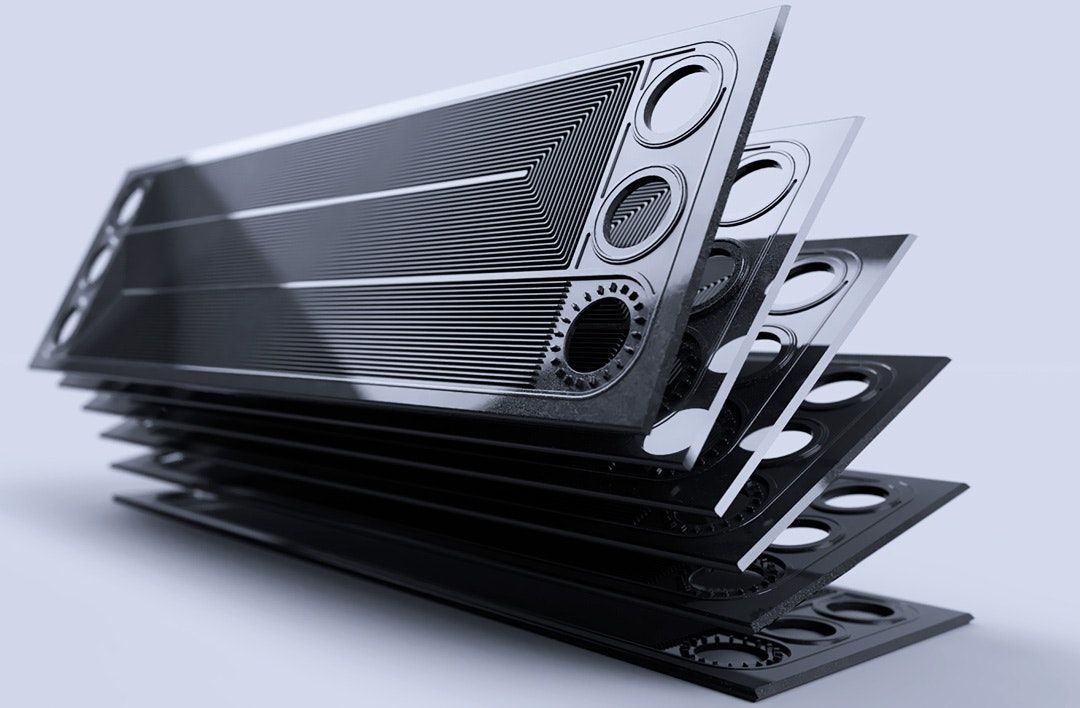

One-step production of asymmetric plates

We produce the world's first z.truded® polymer fuel cell plate with complex design. Unlocking design freedom, efficiency and scalability in one single step.

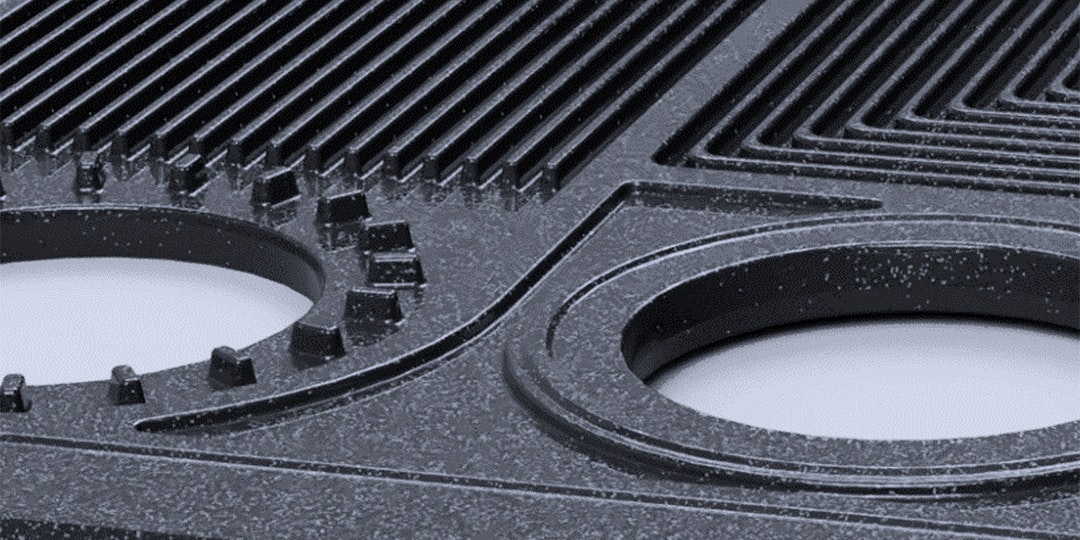

Collaboration with experts

With input from fuel cell authorities around the world, the z.trusion® team is leading the work to produce the plate which is predicted by experts to play a major role in rapidly scaling up the production of fuel cells.

Key facts of the z.truded® bipolar fuel cell plate

Less cost

– z.trusion® manufacturing compared to compression moulding

cost savings

– Upfront investment with z.trusion® compared to compression moulding

Times faster

– Production rate with z.trusion® compared to compression moulding

Energy savings

– Per produced plate with z.trusion® compared to compression moulding