Five ways to save material in next generation products

With material prices skyrocketing, numerous companies are facing challenges in maintaining their competitiveness. Discover how you can optimise your product's weight and materials in five effective ways, not only saving valuable planetary resources but also remaining cost-effective. Achieve these goals effortlessly with the innovative solution of z.trusion®

1. Add ribbs / reinforcements to the structure

By adding reinforcement to a structure you can maintain its physical performance while reducing material needed, in for example a vehicle bumper or roof beam.

2. Increase the surface variation

By adding a 3D texture to a surface you can increase the distance heat has to transfer across the product from A to B, thereby improving insulation performance while reducing material needed.

3. Combine functionality

Integrate functions in one single part to reduce number of components and number of materials needed to realise the product. Like for example combining the fixation of cells with the battery pack structure.

4. Design for zero waste

Avoid after-processes creating material waste, like for example machining. Instead, consider manufacturing methods that make use of only the material needed to manufacture the product, like for example z.trusion®, injection molding or sheet metal forming.

5. Imprint a pattern onto your product

By adding a pattern or structure imprinted in your product you can reduce the material needed for the product while gaining an additional design element. Make sure to use processes generating no waste, like z.trusion®.

Potential material savings with z.trusion®

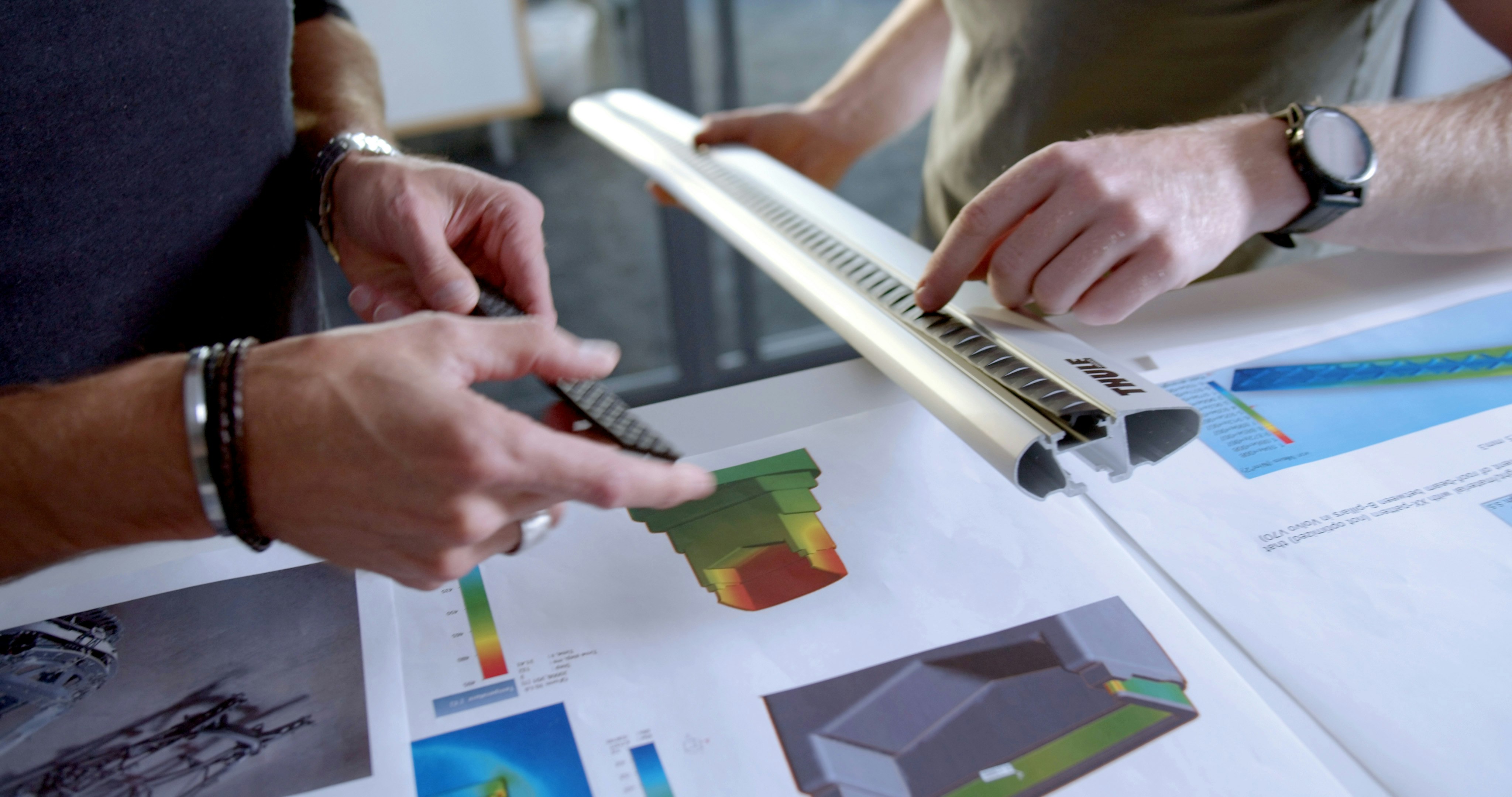

Vehicle bumper beam

Vehicle roof beam

Window thermal break

Tab cooled EV battery pack