3D at the speed of 2D

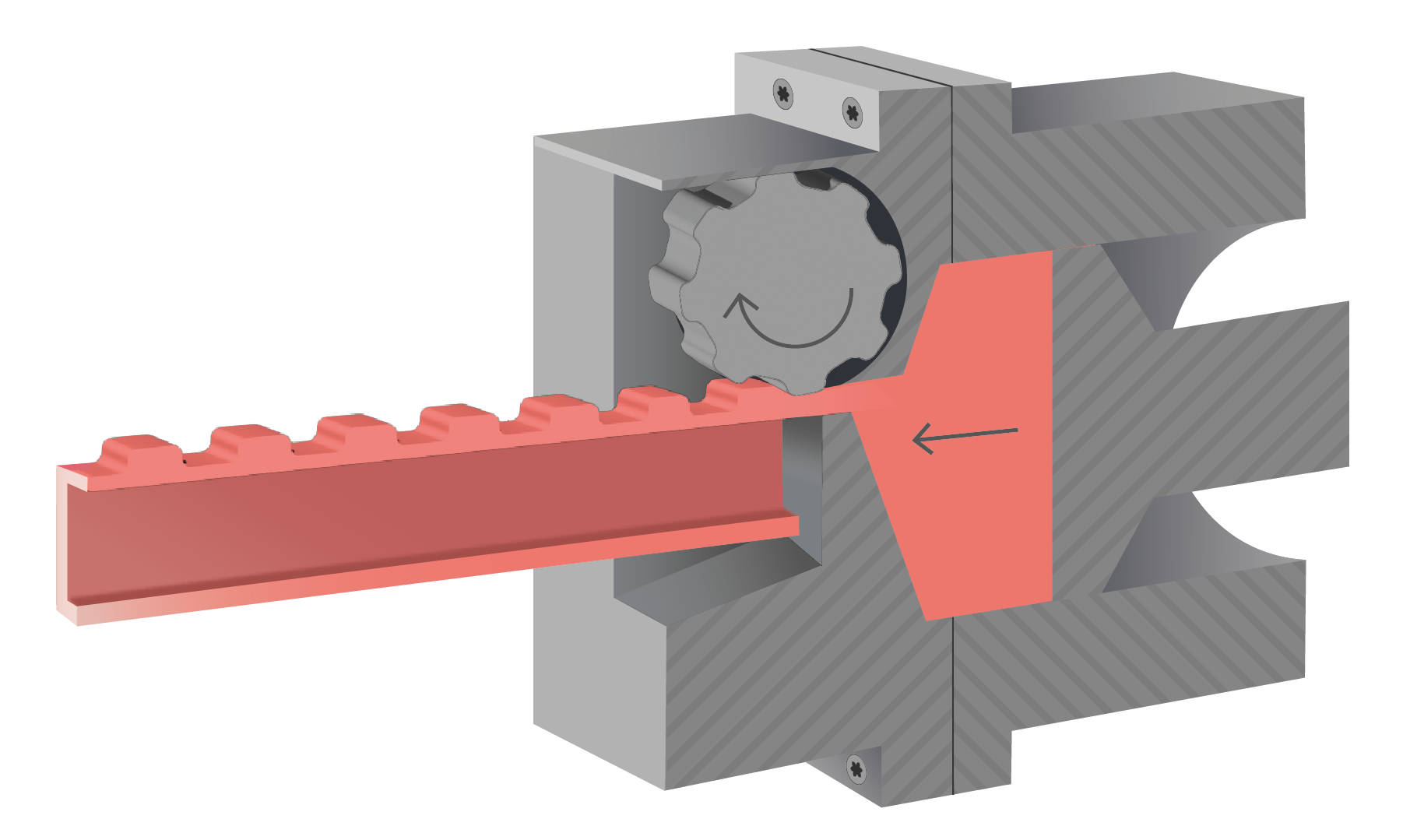

The z.trusion® technology upgrades one of the most commonly used manufacturing technologies in the world, namely extrusion*. By retrofitting the z.trusion® technology onto existing extrusion lines, 3D structures and topologies can be achieved in one easy manufacturing step.

*Extrusion typically involves forcing material through a die to create a continuous profile, but it is limited to a fixed cross-sectional shape.

The invention

The patented z.trusion® technology uses integrated rotating elements in the formable zone of the extruder to manufacture complex structures with remarkable precision and minimal resource consumption and is 100% compatible with any existing extrusion lines.

- 15 patent families

- 42 granted patents

- 53 patent pending

- World wide coverage

The new functionality

"Designers really go crazy when they realise the potential we bring."

Mikael Eklund, CEO at Reliefed, home of z.trusion®

Capabilities

Material

All materials that are normally suitable for extrusion can be used, until proven otherwise. Even some materials which are normally not intended for extrusion are possible to use with z.trusion®.

- Polymer

- Rubber

- Aluminum

- Ceramics

- Composites

- Bio-composites

- Cork composites

Profile width/height

Cut/punch-outs

- Cut-outs are possible along the edge of the profile in the extruded direction

- Punch-outs for holes and other features are possible, depending on the surrounding geometry

- Holes through a profile are possible in certain materials